what to do if codecademy run keeps loading

3D Insider is ad supported and earns money from clicks, commissions from sales, and other ways.

It's not uncommon for a 3D printing project to take upward to 12 hours (or more) to terminate. For this reason, it's near impossible for you to keep watch over a 3D press project for the entire fourth dimension that information technology is running.

This can exist worrying considering how many things can become incorrect during 3D printing. One potential problem is running out of filament in the middle of the projection. What can yous do should this happen? Tin a projection still be saved if you lot run out of filament mid-print?

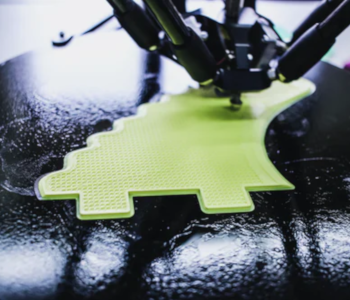

Saving a print that runs out of filament

The worst-case scenario is that your spool runs out of filament without you noticing. If your 3D printer does not take a filament run-out sensor, and so the project volition proceed as if it was still printing with filament. This ways that the nozzle volition continue to move around and that the print head will continue to motion up.

When this happens, continuing the print using the same G-Code file is no longer an pick. It'due south besides as well belatedly to hit "Pause" on your slicer so that you lot can feed new filament into the system. You will have to be a bit more creative to solve this problem.

Take a ruler and measure out the height of your partially finished print. Now go to your slicer software and open the original 3D model you used for the project. Using the measurements y'all took, you will need to "bury" a portion of the model. This will instruct the slicer to generate a G-Lawmaking using only the portion of the model that has non been printed yet.

Unfortunately, laying downwards the new model on the unfinished 1 on your print bed would be a very unreliable grade of action. You lot can endeavour this out past adjusting the z-beginning of your printer, but there'due south a good chance that your layers would non be perfectly aligned.

The almost prudent approach is to start anew for the "residue" of your model. Impress information technology on a clean print bed, as if you were press an entirely new model. In one case you lot're washed the two pieces of your model can be put together using glue. This is, after all, a common technique in 3D printing.

To make the finished production equally seamless equally possible, it would exist all-time to sand and shine the surface of the print. Any visible gaps are best repaired using thick glue or a space-filling epoxy solution. Finally, use a layer of pigment to your finished print to perfectly render the seam between the 2 parts invisible.

What to do if your filament is about to run out

If you have the adventure to intervene before your filament runs out, and then you have a much smaller problem on mitt. Most 3D printers have a provision for swapping in new filament only by pausing the electric current chore. This volition bring back the print head to the home position so that y'all tin pull out the leftover filament and replace it with filament from another spool.

Once the impress caput has stopped moving, simply pull the extruder lever, pull out the leftover filament, and feed in the new filament. Continuing the project should move the impress head correct where it left off without any manual intervention from you. This method is a lot easier to exercise if your 3D printer has a direct extruder.

This method of pausing the print and swapping in new filament can fifty-fifty exist done deliberately to brand a print out of multiple filament colors. If you know how to edit a G-Code, yous can plan it to automatically pause at a specific height or layer count. This will give you the chance to swap in a filament of another colour. This is ane of the more than mutual ways to make multicolor prints even if your 3D printer merely has a single extruder.

Employ a filament run-out sensor

A worry-free pick is to utilize a 3D printer that comes with a filament run-out sensor. If your 3D printer does not have ane, you tin can too buy a third-party sensor that can interface with the board of your 3D printer.

A filament run-out sensor is installed correct before the feeder gear. This is a fairly simple sensor that can detect if there is no more than filament running through its PTFE tube. This signal is and so relayed to the controller board to tell the 3D printer to intermission printing. This gives ample time for you to swap out a fresh spool of filament.

Since the sensor is installed at the feeder gear, information technology stops the 3D printer at a betoken where it'south yet extruding some filament. Every bit long as y'all act fast, you should be able to pick upwardly where yous left off.

Measuring your leftover filament

If printing with filament that you know will run out is causing you anxiety, and then the all-time precautionary measure is to make sure that it does not run out at all. The adept news is that you don't demand any fancy equipment or sensor to do this. All you will demand is a digital weighing calibration.

When you load a model into a slicer, it volition typically requite you an estimate of how much filament would exist needed to 3D print the model. The problem is that the gauge is usually given in terms of the length of the filament. The length of filament in that leftover spool may non exist data that is immediately available to y'all, only we tin deduce it through simple math.

The showtime slice of information yous will need is the weight of the empty spool of your filament. This is either printed on the spool itself or indicated on the manufacturer'south website. If this isn't immediately available, then arrive bear on with the manufacturer of your filament – they should be able to requite you a number.

The adjacent step is to weigh your partially consumed spool of filament. Decrease the weight of the remaining filament. From here on, nosotros volition have to make a few calculations. Nosotros will assume that your leftover filament weighs 250 grams and that you are press with a one.75-mm ABS filament.

Due west, weight of the filament = 250 grams

D, diameter of the filament = i.75 mm OR 0.175 cm

P, density of the filament = i.04 1000 / cm3 (ABS)

A, filament cross-section area = iii.14 * (D/2)2

= iii.xiv * (0.175 cm / two )ii

= 0.02404 cm2

V, book of filament = W / P

= 250 grams / 1.04 grams / cm3

= 240.38 cm3

L, length of filament = V / A

= 240.38 cm3 / 0.02404 cm2

= ix,999 cm OR 99 meters

This means that a spool of ane.75 mm ABS filament that weighs 250 grams will take a length of about 99 meters. This method assumes a few things that may non be completely accurate, such as the weight of the empty spool or that the filament has a abiding bore throughout its length.

Just to be prophylactic, leave a ten to 20 percent buffer between the length that your project needs and the bodily length of the filament. If you are estimating that you have about 99 meters of filament left, then make sure that your model requires less than 90 meters.

Last thoughts

Running out of filament in the eye of a print is something that you will inevitably come across while 3D printing. The all-time measure is to prevent it from happening in the commencement place, whether past calculating the length of leftover filament in your spool or to use a run-out sensor.

However, don't fret if your 3D printing project runs out of filament mid-print. Even if the nozzle has moved far away from your partially finished print, there'southward still a way to salvage it through artistic post-processing.

3D printers should never be left unattended. They can pose a firesafety hazard.

hernandezevervall.blogspot.com

Source: https://3dinsider.com/running-out-of-filament/

0 Response to "what to do if codecademy run keeps loading"

Post a Comment